IoT Applications

Use PLC Acquisition Gateway to Realize Intelligent Management and Operation of Sewage Treatment Plants

Views : 5415

Author : Jeakie

Update time : 2023-03-30 15:35:48

Use PLC Acquisition Gateway to Realize Intelligent Management and Operation of Sewage Treatment Plants

Background of the project:

There are many key equipment status and process parameters in sewage treatment plants that need to be monitored and managed. The following are some of the more important ones:

1. Sewage pump status: including sewage pump current, voltage, water level, pressure and other parameters. Real-time monitoring can ensure the normal operation of the sewage pump and prevent sewage pump damage and accidents.

2. Status of sewage treatment equipment: For example, parameters such as the working status, load and running time of aerators, filters, dosing pumps and other equipment. Real-time monitoring can ensure the normal and safe operation of the equipment.

3. Water quality parameters: including turbidity, COD, NH3-N, TP and other water quality indicators. Through real-time monitoring, the status and changes of water quality can be understood, and the operating parameters can be adjusted in time during the treatment process to avoid water quality deterioration.

4. Temperature and PH value: These parameters are closely related to the sewage treatment process. Through real-time monitoring, the operating parameters can be adjusted to ensure the effectiveness and efficiency of the treatment process.

5. Sludge concentration and sludge dry humidity: These parameters reflect the status and treatment effect of sludge. Through real-time monitoring, the sludge treatment process can be adjusted to achieve better treatment effect.

6. Power supply status: including parameters such as voltage, current, and electric energy. Through real-time monitoring, accidents can be prevented and the safe operation of equipment can be ensured.

To sum up, the status of equipment and process parameters in sewage treatment plants are very important. Real-time monitoring and management can ensure the normal operation and efficient treatment of equipment, so as to achieve better treatment effects and ensure water quality safety. Project requirements:

Project requirements:

Customers mainly do platform planning, design, construction and implementation. Therefore, the project mainly needs to collect the relevant equipment status and process parameters of the sewage treatment plant. Siemens 1200 PLC is used to transfer to the enterprise operation cloud platform through 4G and MQTT.

An Introduction:

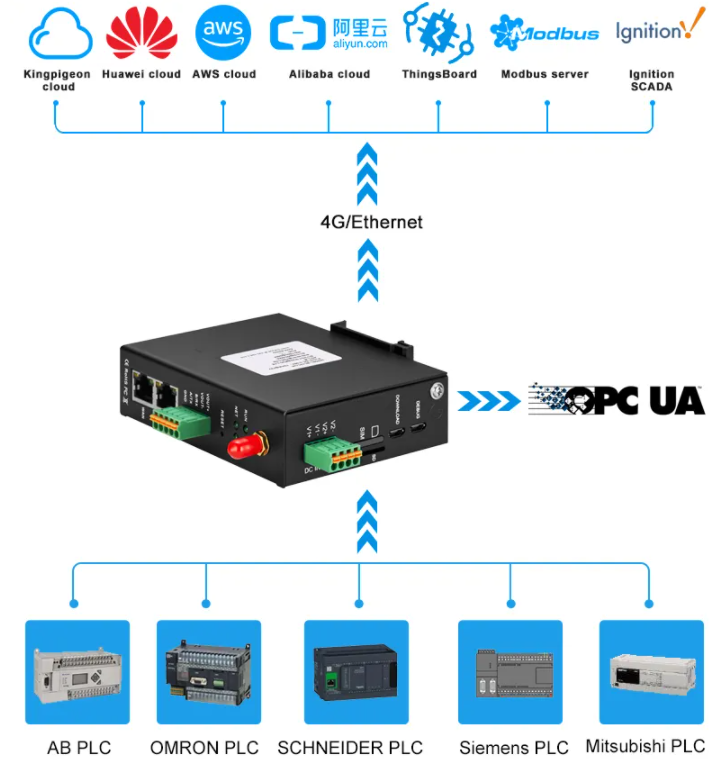

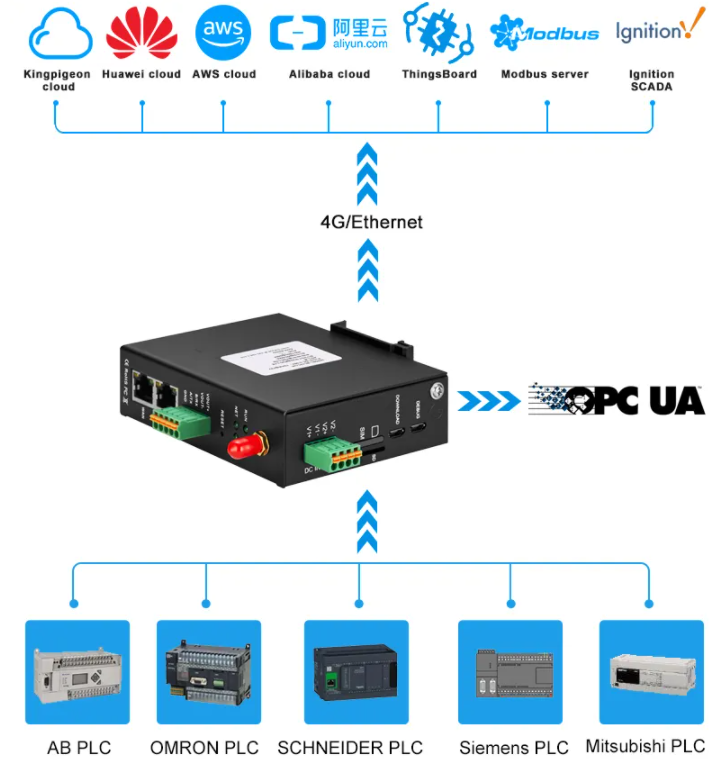

BLIIOT BL102 PLC gateway is a device commonly used in the field of industrial automation, which can realize data collection, processing, transmission and monitoring of different types of devices.

In a sewage treatment plant, the BL102 PLC gateway can be used to collect relevant equipment status, process parameters and other data to improve sewage treatment capacity and efficiency. The specific implementation is as follows:

The specific implementation is as follows:

1. Install the BL102 PLC gateway in the communication control room or other suitable locations, and connect it to the Siemens 1200 PLC in the sewage treatment plant.

2. Configure the BL102 PLC gateway, including setting acquisition parameters, data transmission methods, communication protocols, etc.

3. Real-time collection of data such as status and process parameters of related equipment in sewage treatment plants, such as pump voltage, current, temperature, pressure and other information.

4. The processed data is transmitted to the enterprise operation cloud platform through 4G for analysis and processing, such as real-time monitoring, alarm, abnormal diagnosis, statistical analysis and other operations.

Through the BL102 PLC gateway, real-time monitoring of the status and process parameters of sewage treatment plant equipment can be realized, and the data can be processed and transmitted flexibly to improve the efficiency of sewage treatment and the ability of real-time monitoring, so as to achieve a higher level and quality.

Background of the project:

There are many key equipment status and process parameters in sewage treatment plants that need to be monitored and managed. The following are some of the more important ones:

1. Sewage pump status: including sewage pump current, voltage, water level, pressure and other parameters. Real-time monitoring can ensure the normal operation of the sewage pump and prevent sewage pump damage and accidents.

2. Status of sewage treatment equipment: For example, parameters such as the working status, load and running time of aerators, filters, dosing pumps and other equipment. Real-time monitoring can ensure the normal and safe operation of the equipment.

3. Water quality parameters: including turbidity, COD, NH3-N, TP and other water quality indicators. Through real-time monitoring, the status and changes of water quality can be understood, and the operating parameters can be adjusted in time during the treatment process to avoid water quality deterioration.

4. Temperature and PH value: These parameters are closely related to the sewage treatment process. Through real-time monitoring, the operating parameters can be adjusted to ensure the effectiveness and efficiency of the treatment process.

5. Sludge concentration and sludge dry humidity: These parameters reflect the status and treatment effect of sludge. Through real-time monitoring, the sludge treatment process can be adjusted to achieve better treatment effect.

6. Power supply status: including parameters such as voltage, current, and electric energy. Through real-time monitoring, accidents can be prevented and the safe operation of equipment can be ensured.

To sum up, the status of equipment and process parameters in sewage treatment plants are very important. Real-time monitoring and management can ensure the normal operation and efficient treatment of equipment, so as to achieve better treatment effects and ensure water quality safety.

Customers mainly do platform planning, design, construction and implementation. Therefore, the project mainly needs to collect the relevant equipment status and process parameters of the sewage treatment plant. Siemens 1200 PLC is used to transfer to the enterprise operation cloud platform through 4G and MQTT.

An Introduction:

BLIIOT BL102 PLC gateway is a device commonly used in the field of industrial automation, which can realize data collection, processing, transmission and monitoring of different types of devices.

In a sewage treatment plant, the BL102 PLC gateway can be used to collect relevant equipment status, process parameters and other data to improve sewage treatment capacity and efficiency.

1. Install the BL102 PLC gateway in the communication control room or other suitable locations, and connect it to the Siemens 1200 PLC in the sewage treatment plant.

2. Configure the BL102 PLC gateway, including setting acquisition parameters, data transmission methods, communication protocols, etc.

3. Real-time collection of data such as status and process parameters of related equipment in sewage treatment plants, such as pump voltage, current, temperature, pressure and other information.

4. The processed data is transmitted to the enterprise operation cloud platform through 4G for analysis and processing, such as real-time monitoring, alarm, abnormal diagnosis, statistical analysis and other operations.

Through the BL102 PLC gateway, real-time monitoring of the status and process parameters of sewage treatment plant equipment can be realized, and the data can be processed and transmitted flexibly to improve the efficiency of sewage treatment and the ability of real-time monitoring, so as to achieve a higher level and quality.