I/O System

OPC UA I/O System

Item No.: BL215

Introduction

Features

Specifications

Download

Applications

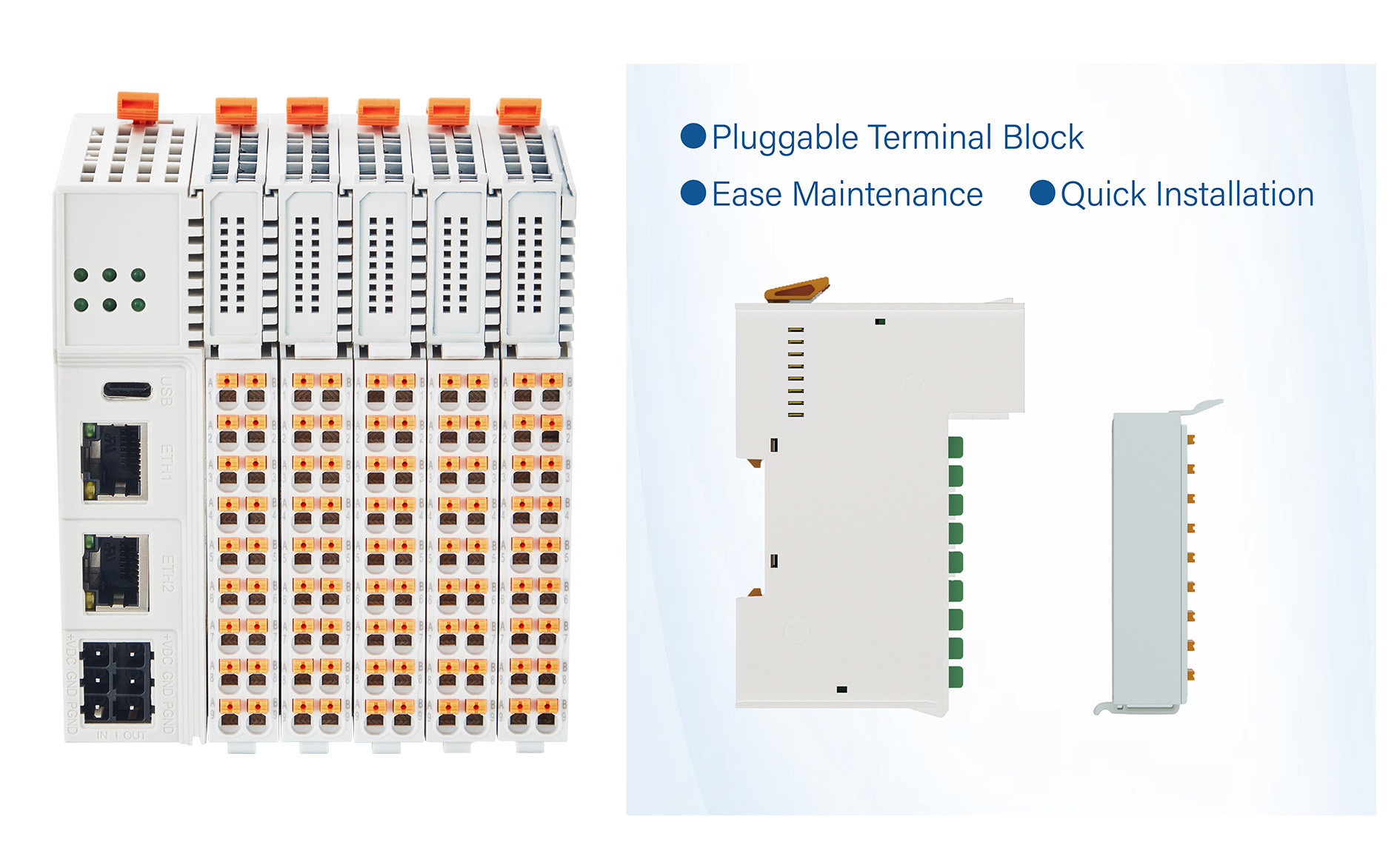

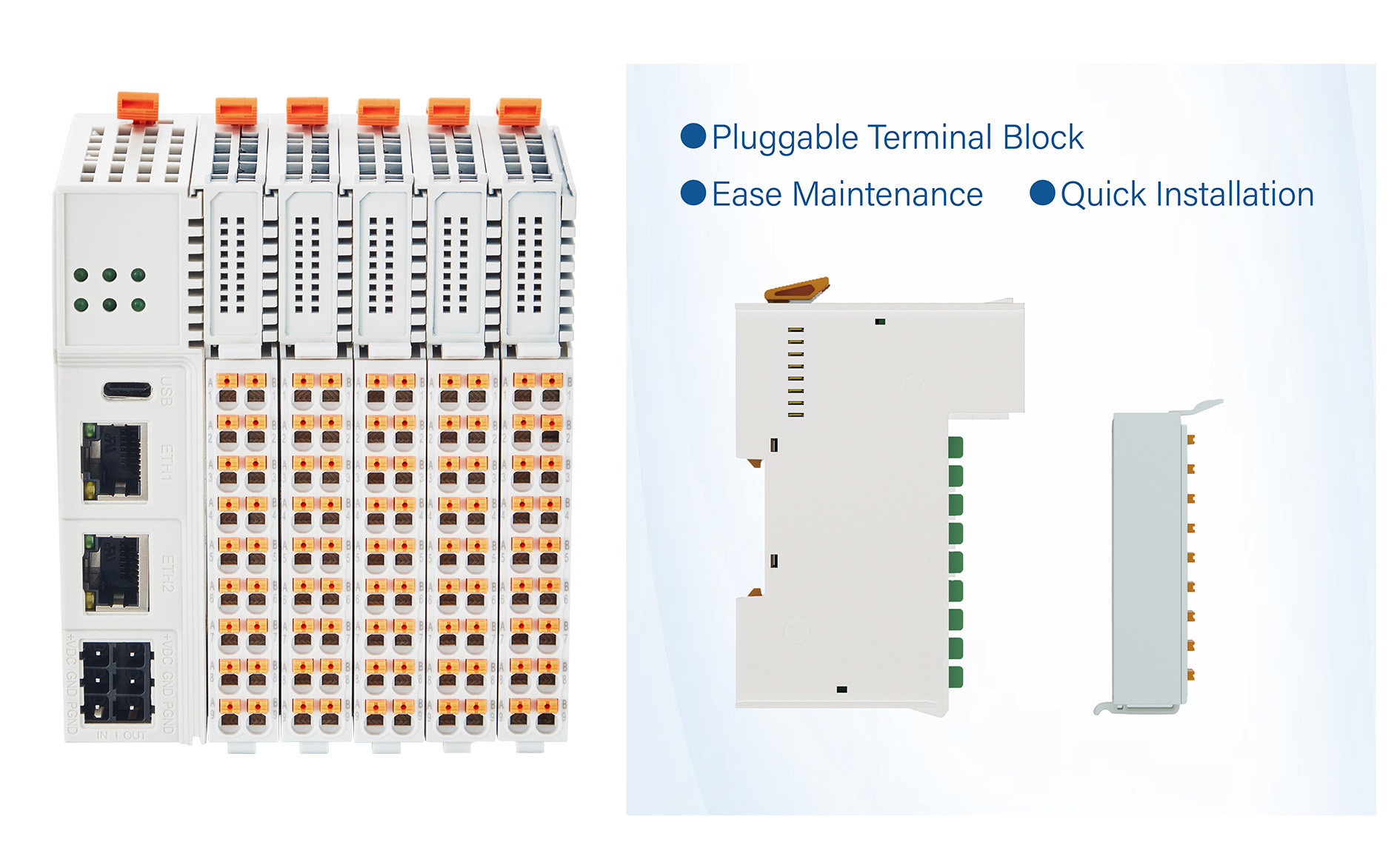

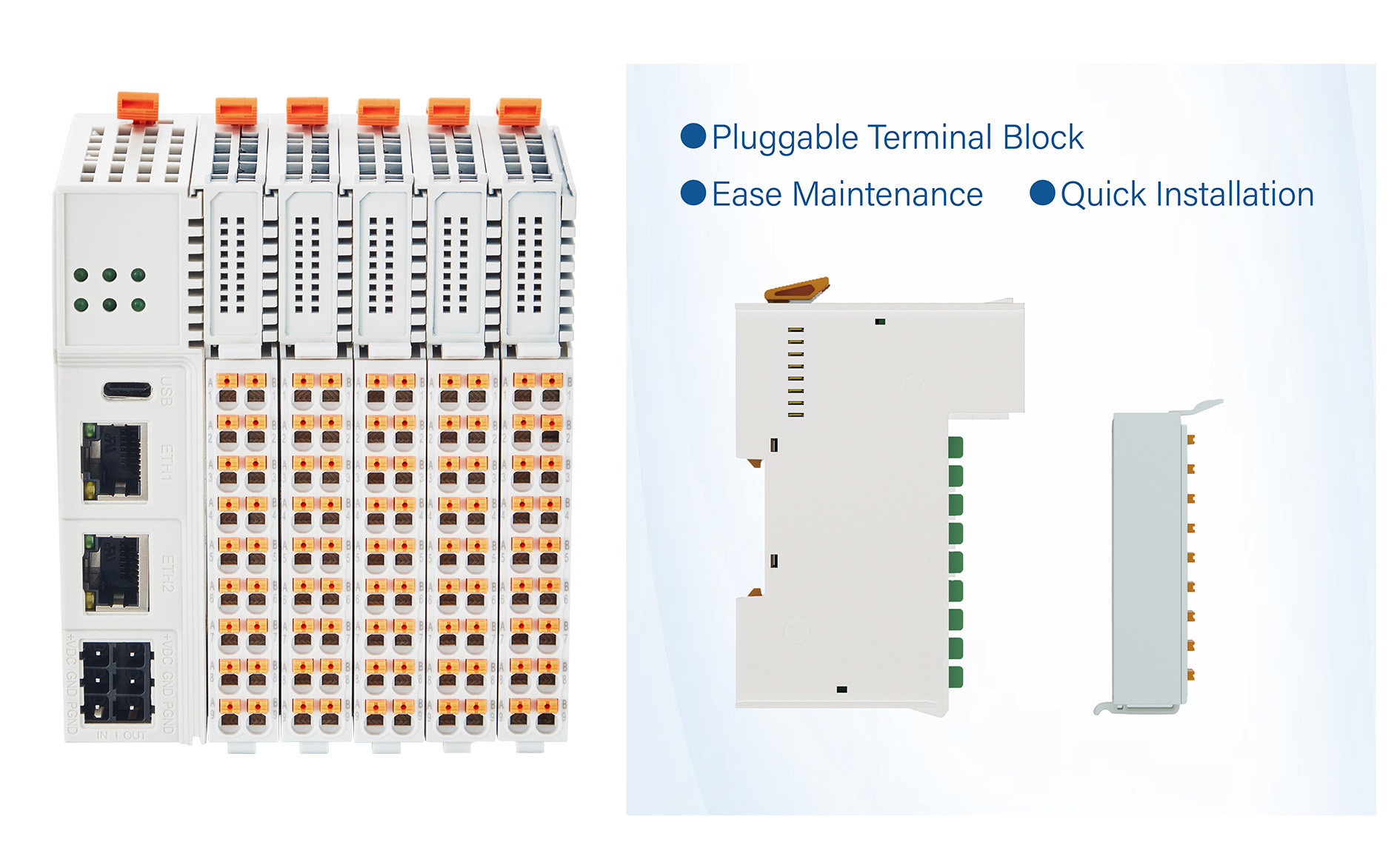

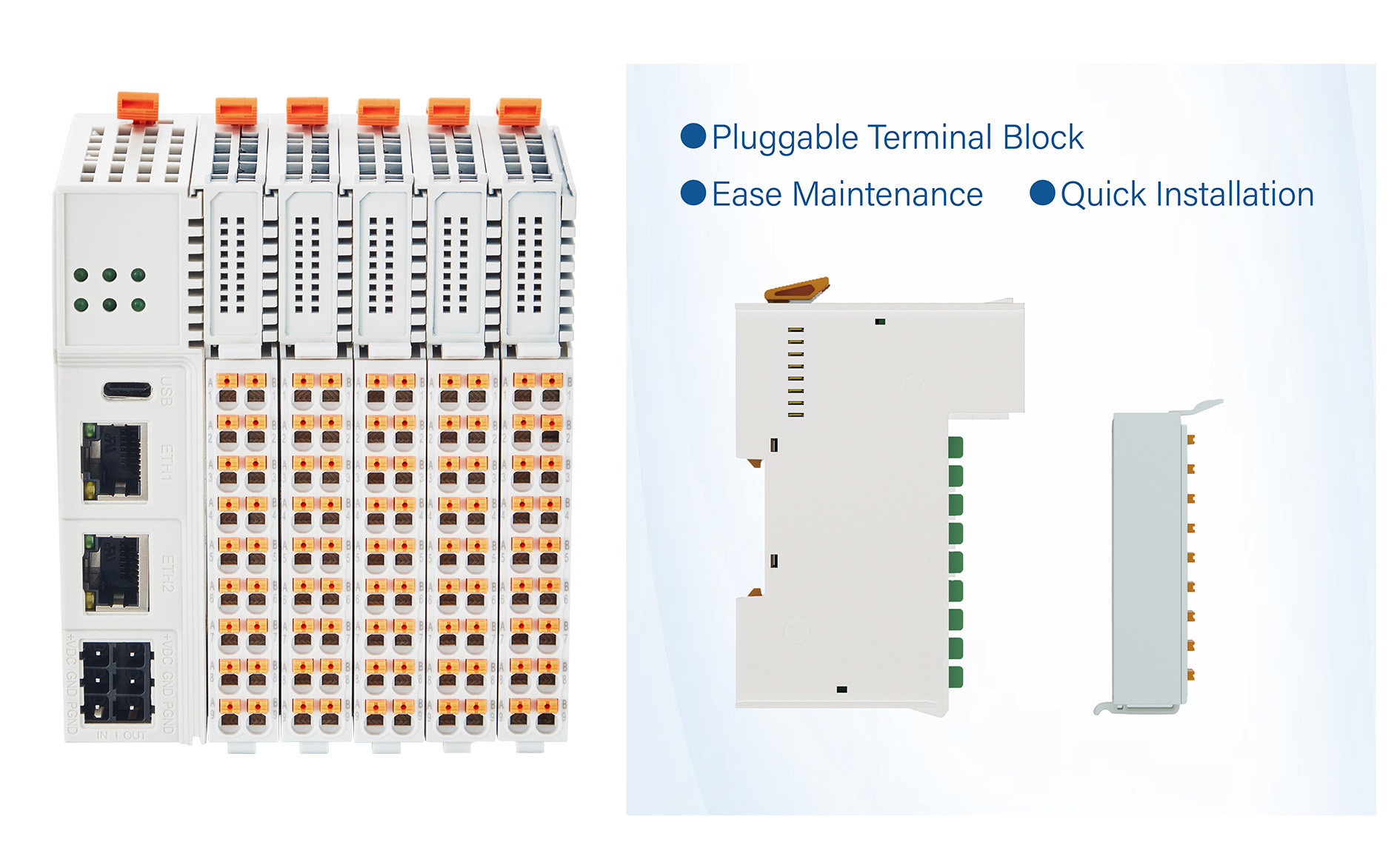

BLIIOT OPC UA I/O system BL215 based on next-generation Industrial Internet technology. It features plug-and-play installation without the need for tools and emphasizes stability as a primary characteristic. This coupler is designed to directly interface with SCADA, MES, MOM, ERP, and other IT systems, seamlessly bridging the Operational Technology (OT) and Information Technology (IT) layers. It represents the optimal solution for IO systems in Industrial Internet, Industry 4.0, Smart Manufacturing, and Digital Transformation solutions.

The OPC UA Coupler BL215 is designed with industrial-grade components and complies with EMC (Electromagnetic Compatibility) and EMI (Electromagnetic Interference) testing standards. This coupler provides dual Ethernet ports to support switch cascade functionality. It supports the standard OPC UA protocol and includes 1 RS485 interface, enabling Modbus RTU to OPC UA protocol conversion.

The OPC UA Coupler BL215 features web-based configuration and operates as an OPC UA Server. It can be expanded with up to 32 modules from the N-series, offering various functionalities including DI (Digital Input), DO (Digital Output), AI (Analog Input), AO (Analog Output), PWM (Pulse Width Modulation), high-speed pulse counting, thermocouples, and more.

Using a high-speed backplane bus, the coupler can handle up to 32 slave stations with a maximum scan cycle of 10ms when fully loaded. It includes built-in diagnostic functions to monitor IO module communication status in real-time and provides a 2000mA driving circuit for IO modules.

The OPC UA Coupler BL215 features a stable and reliable snap-in connection structure, with separate wiring terminals from the IO modules, allowing for plug-and-play installation without the need for tools. Its ultra-thin design concept enables seamless integration into Industrial Internet, Industry 4.0, Smart Manufacturing, and Digital Transformation solutions by bridging the gap between Information Technology (IT) and Operational Technology (OT) layers. This makes it the ideal choice for IO systems in these advanced industrial applications.

The OPC UA Coupler BL215 is designed with industrial-grade components and complies with EMC (Electromagnetic Compatibility) and EMI (Electromagnetic Interference) testing standards. This coupler provides dual Ethernet ports to support switch cascade functionality. It supports the standard OPC UA protocol and includes 1 RS485 interface, enabling Modbus RTU to OPC UA protocol conversion.

The OPC UA Coupler BL215 features web-based configuration and operates as an OPC UA Server. It can be expanded with up to 32 modules from the N-series, offering various functionalities including DI (Digital Input), DO (Digital Output), AI (Analog Input), AO (Analog Output), PWM (Pulse Width Modulation), high-speed pulse counting, thermocouples, and more.

Using a high-speed backplane bus, the coupler can handle up to 32 slave stations with a maximum scan cycle of 10ms when fully loaded. It includes built-in diagnostic functions to monitor IO module communication status in real-time and provides a 2000mA driving circuit for IO modules.

The OPC UA Coupler BL215 features a stable and reliable snap-in connection structure, with separate wiring terminals from the IO modules, allowing for plug-and-play installation without the need for tools. Its ultra-thin design concept enables seamless integration into Industrial Internet, Industry 4.0, Smart Manufacturing, and Digital Transformation solutions by bridging the gap between Information Technology (IT) and Operational Technology (OT) layers. This makes it the ideal choice for IO systems in these advanced industrial applications.

Description

BLIIOT OPC UA I/O system BL215 based on next-generation Industrial Internet technology. It features plug-and-play installation without the need for tools and emphasizes stability as a primary characteristic. This coupler is designed to directly interface with SCADA, MES, MOM, ERP, and other IT systems, seamlessly bridging the Operational Technology (OT) and Information Technology (IT) layers. It represents the optimal solution for IO systems in Industrial Internet, Industry 4.0, Smart Manufacturing, and Digital Transformation solutions.

The OPC UA Coupler BL215 is designed with industrial-grade components and complies with EMC (Electromagnetic Compatibility) and EMI (Electromagnetic Interference) testing standards. This coupler provides dual Ethernet ports to support switch cascade functionality. It supports the standard OPC UA protocol and includes 1 RS485 interface, enabling Modbus RTU to OPC UA protocol conversion.

The OPC UA Coupler BL215 features web-based configuration and operates as an OPC UA Server. It can be expanded with up to 32 modules from the N-series, offering various functionalities including DI (Digital Input), DO (Digital Output), AI (Analog Input), AO (Analog Output), PWM (Pulse Width Modulation), high-speed pulse counting, thermocouples, and more.

Using a high-speed backplane bus, the coupler can handle up to 32 slave stations with a maximum scan cycle of 10ms when fully loaded. It includes built-in diagnostic functions to monitor IO module communication status in real-time and provides a 2000mA driving circuit for IO modules.

The OPC UA Coupler BL215 features a stable and reliable snap-in connection structure, with separate wiring terminals from the IO modules, allowing for plug-and-play installation without the need for tools. Its ultra-thin design concept enables seamless integration into Industrial Internet, Industry 4.0, Smart Manufacturing, and Digital Transformation solutions by bridging the gap between Information Technology (IT) and Operational Technology (OT) layers. This makes it the ideal choice for IO systems in these advanced industrial applications.

The OPC UA Coupler BL215 is designed with industrial-grade components and complies with EMC (Electromagnetic Compatibility) and EMI (Electromagnetic Interference) testing standards. This coupler provides dual Ethernet ports to support switch cascade functionality. It supports the standard OPC UA protocol and includes 1 RS485 interface, enabling Modbus RTU to OPC UA protocol conversion.

The OPC UA Coupler BL215 features web-based configuration and operates as an OPC UA Server. It can be expanded with up to 32 modules from the N-series, offering various functionalities including DI (Digital Input), DO (Digital Output), AI (Analog Input), AO (Analog Output), PWM (Pulse Width Modulation), high-speed pulse counting, thermocouples, and more.

Using a high-speed backplane bus, the coupler can handle up to 32 slave stations with a maximum scan cycle of 10ms when fully loaded. It includes built-in diagnostic functions to monitor IO module communication status in real-time and provides a 2000mA driving circuit for IO modules.

The OPC UA Coupler BL215 features a stable and reliable snap-in connection structure, with separate wiring terminals from the IO modules, allowing for plug-and-play installation without the need for tools. Its ultra-thin design concept enables seamless integration into Industrial Internet, Industry 4.0, Smart Manufacturing, and Digital Transformation solutions by bridging the gap between Information Technology (IT) and Operational Technology (OT) layers. This makes it the ideal choice for IO systems in these advanced industrial applications.

introduction

Features

Specifications

Download

Applications